Oil System Comparison

HP+ AND RS HIGH VOLUME OIL PUMPS

OIL COOLED

•27% MORE PRESSURE GEAR VOLUME

•27% MORE SCAVENGE GEAR VOLUME

WATER COOLED

•30% MORE PRESSURE GEAR VOLUME

•53% MORE SCAVENGE GEAR VOLUME

HP+ AND RS OILING SYSTEMS (PUMP/PLATE) - OIL & WATER COOLED

•42% More scavenging with MATCHED OIL PASSAGES

•68% more oil to the crank and connecting rod

•15 -25 DEGREE COOLER ENGINE TEMPS

•15 -30 DEGREE COOLER OIL TEMPS

•10 -30 MORE OIL PSI

•Sump level reduction

RACE SERIES KITS INCLUDE:

- FULL TRAVEL SLOW SLOW BLEED DOWN LIFTERS WHICH ARE QUIETER & INCREASE RPM BEFORE VALVE FLOAT

- OIL PUMP IS BILLET 7075 ALUMINUM WHICH 50% HARDER AND STRONGER THAN OEM AND HP+, RED ANODIZED WITH LARGER LARGER SCAVENGE KIDNEY PORTING SCAVENGINGPROMOTING PROMOTING MORE CRANNKCASE SCAVENGING.

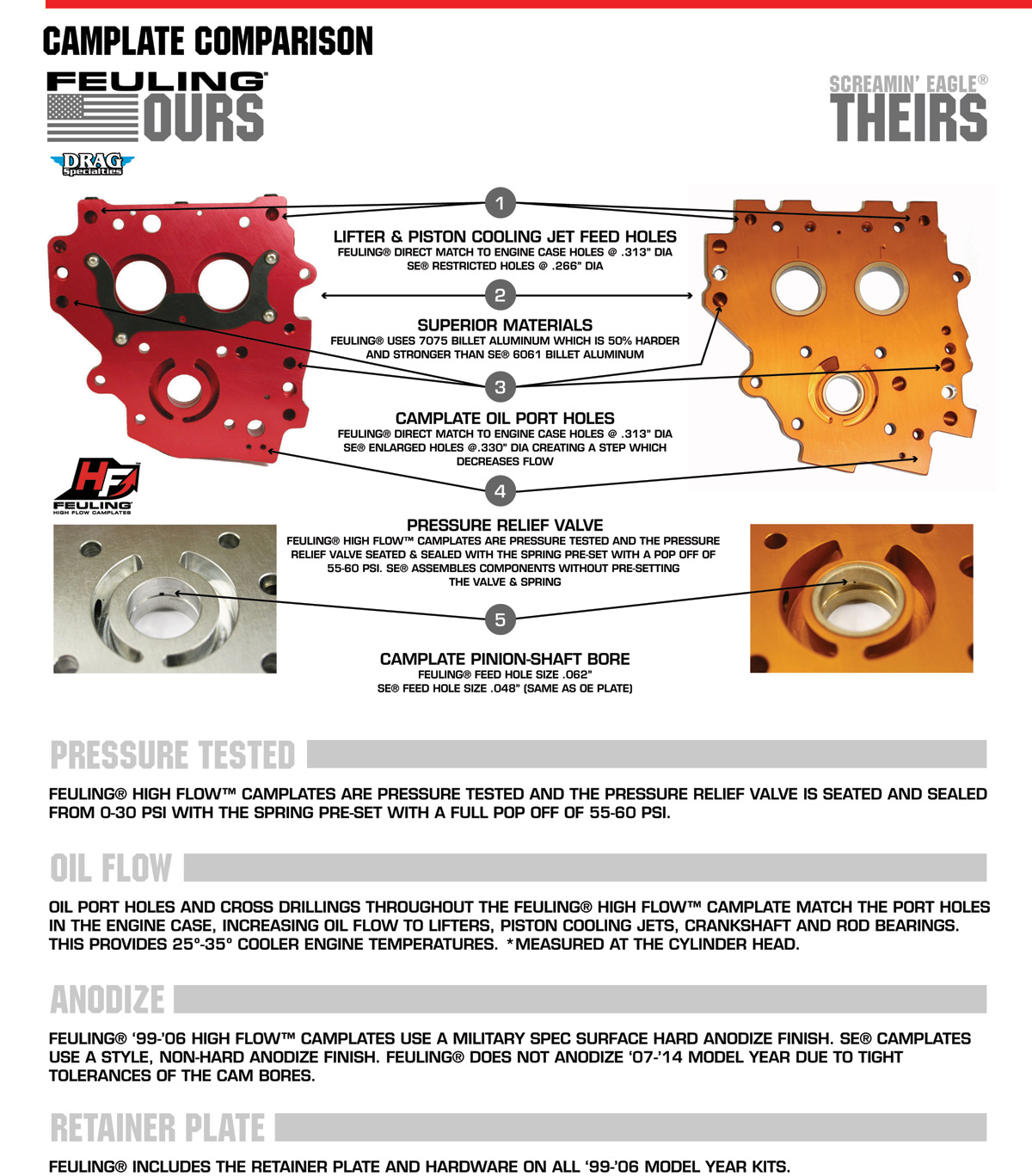

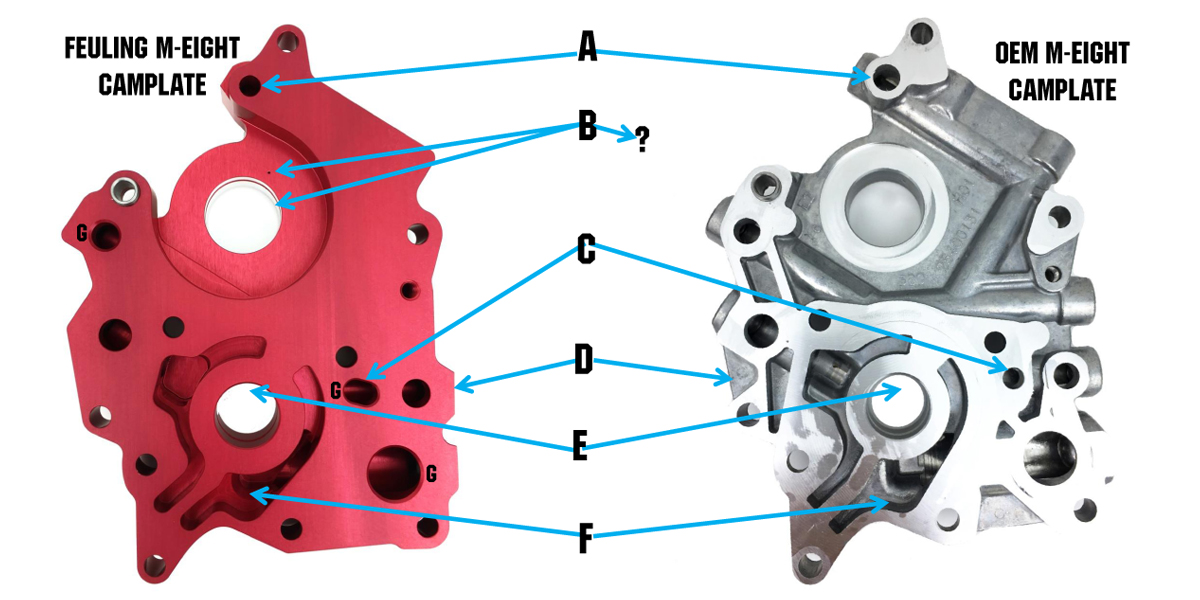

- A = FEULING OIL HOLE MATCHED TO CASE HOLE, OEM has the hole too large creating a step AT ENGINE CASE

- B = FEULING HAS OIL FEED HOLES FOR CAM THRUSTING SURFACES AND OIL GROOVE IN CAM BORE FOR COLD START UP, OEM ZILTCH

- C = Feuling has 42% More scavenging with MATCHED OIL PASSAGE volume to engine case

- D = FEULING CAMPLATES MACHINED FROM BILLET 7075 ALUMINUM WHICH IS 50% HARDER AND STRONGER THAN THE OEM CAST

- E = Feuling sends 68% more oil to the crank and connecting rod

- F = Feuling has larger kidneys promoting more oil flow and volume

- G = FEULING HAS LARGE CHAMFERS ON PASSAGES ENTERING INTO CAMPLATE FOR A SMOOTH TRANSITION, OEM HAS SHARP EDGES

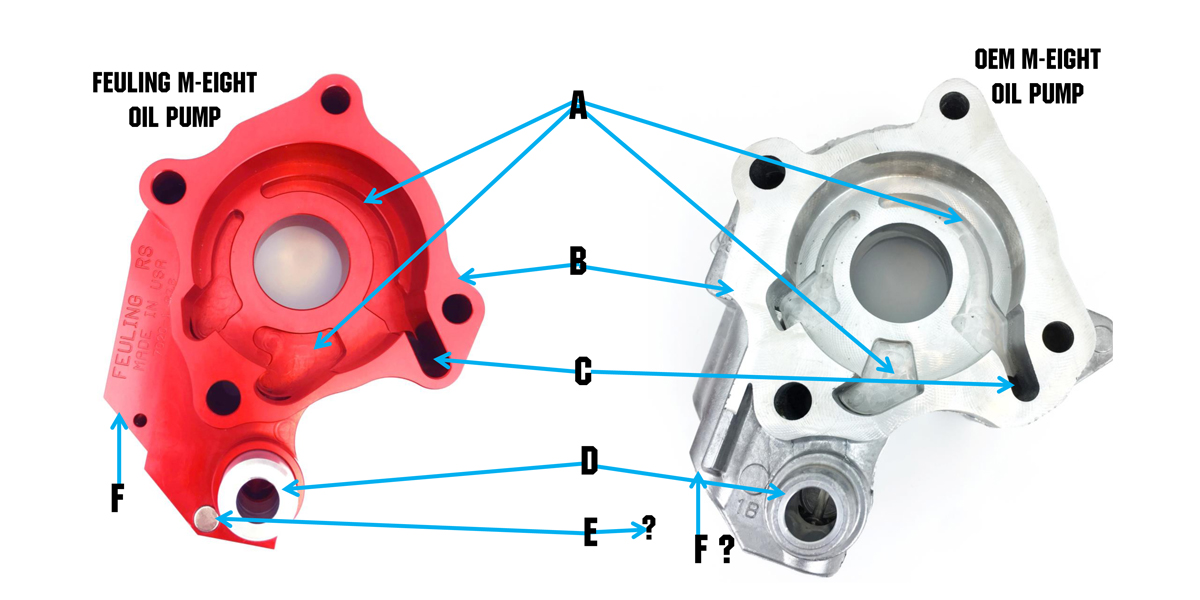

- A = Feuling pumps HAVE larger deeper kidney ports, ON BOTH PRESSURE AND SCAVENGE WITH LARGER DIAMETER HIGHFLOW GEARS

- B = FEULING PUMPS ARE MACHINED FROM BILLET ALUMINUM, hp+ FROM 6061 & RACE SERIES FROM 7075, OEM PUMP IS A CASTING. NOTE 7075 ALUMINUM IS 50% Harder & STRONGER THAN 6061 & OEM CAST MATERIAL, 7075 ALSO HOLDS TIGHTER TOLERANCE UNDER TEMPERATURES

- C = Feuling Increased scavenge port passage by 42%, MATCHING VOLUME/BORES TO ENGINE CASE, OEM SEVERLY RESTRICTED

- D = FEULING PUMPS SCAVENGE PORT PICK UP BORE AND INTERNAL PASSAGES ARE MATCHED TO ENGINE CASE, OEM HAS STEPS

- E = Feuling pumps have magnets to help protect gears and relief valve FROM DEBRIS

- F = FEULING PRESSURE RELIEF VALVE IS SEATED AND SEALED WITH FULL POP OFF AT 60PSI AND SET TO RE SEAT/SEAL AT MIN OF 30PSI The oem pump is assembled without testing and the latest oem design is unable to be tested

Oiling System Comparison

|

|

|  |

|---|---|---|---|

| OIL PUMPS | |||

| Made in the U.S.A | X |

X |

X |

| Hand Measured and Matched Gear Sets | X |

X |

X |

| Preciesion Machined 6061 Oil Pump Housing | X |

X |

|

| Preciesion Machined 7075 Oil Pump Housing | X |

||

| 2" Chrome Moly Gerotor Gears | X |

||

| 2" High Flow Chrome Moly Gerotor Gears | X |

X |

|

| Red Anodized Oil Pump Housing | X |

||

| CAMPLATES | |||

| Made in the U.S.A | X |

X |

X |

| Preciesion Machined 6061 Camplate | X |

||

| Preciesion Machined 7075 Camplate | X |

X |

|

| Hand Set and Tested Pressure Relief Valve | X |

X |

X |

| Red Anodized Camplate | X |

X |

|

| Enlarged Oil Passages | X |

X |

|

| Camplate Oil Ports Matched to Case Ports | X |

X |

|

| LIFTERS | |||

| Include Lifters | X |

X |

|

| Made in the U.S.A | X |

X |

|

| 0.200" Travel | X |

X |

|

| Slower Bleed Down Rate | X |

||

| Increased Roller Clearance | X |

||

| BENEFITS | |||

| Increase Oil Pressure | X |

X |

X |

| Increases Horse Power and Torque | X |

X |

|

| 15-30 Degree Cooler Oil Temperatures | X |

X |

|

| 25-35 Degreee Cooler Egnine Temperatures | X |

X |

|

| ADDITIONAL INFORMATION | |||

| Includes Assembly Lube | X |

X |

X |

| Includes Quick Change Gasket Kit | X |

X |

|